News

Development of PFAS-Free Electroless Composite Plating to Replace PTFE Composite Plating

Info

2024.02.09

Patent filed for industry-first new technology for sliding parts in automobiles etc.

Nihon Kagaku Sangyo Co., Ltd. (President: YANAGISAWA Eiji) is pleased to announce that it has newly developed an electroless composite plating that does not contain per- and polyfluoroalkyl substances (PFAS)—substances that are seen as a concern in the EU and other parts of the world due to their impact on the human health and the natural environment—and has filed patent application for the technology.

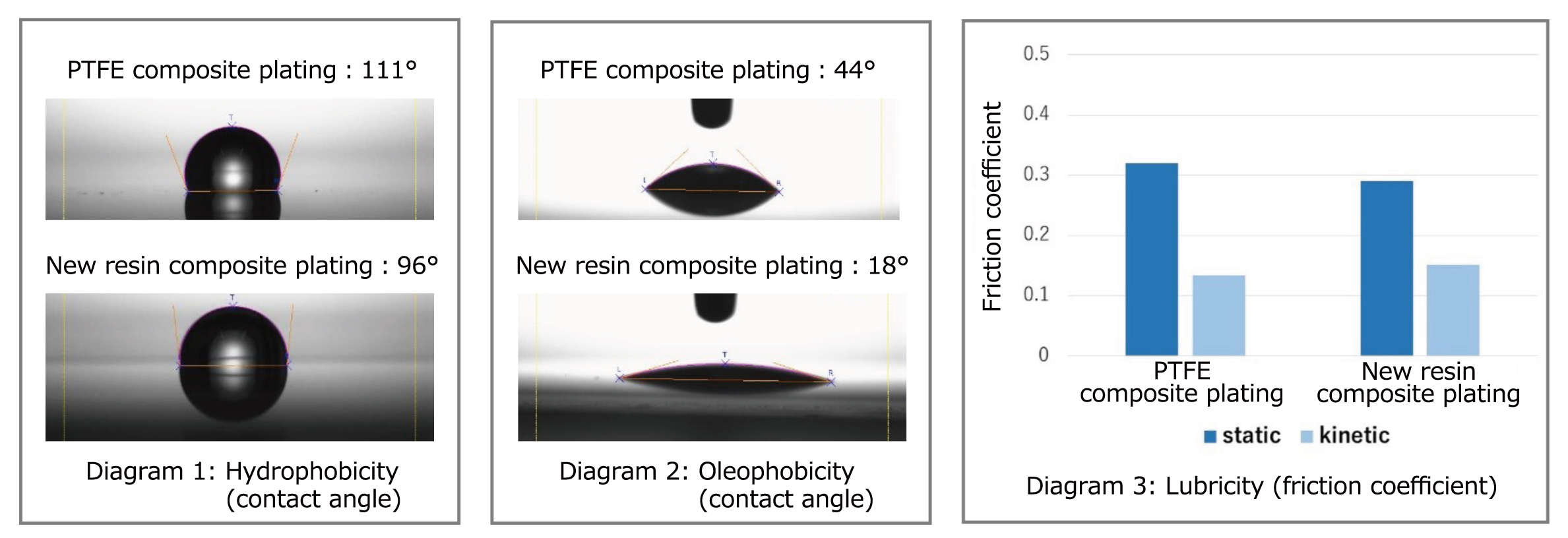

This technology is notable in that the newly developed plating is as hydrophobic and lubricious as the more conventional, commonly used polytetrafluoroethylene (PTFE) composite plating, yet is less oleophobic than PTFE composite plating. Owing to such characteristics, the new product is expected to maintain a high level of oil retention even in the presence of lubricant oil and demonstrate high lubricity. For this reason, we believe this new technology provides promising application in sliding parts, e.g. those used in automobiles.

Background to the development

Generally, PTFE composite plating has a low friction coefficient and superb durability, and it is therefore widely used in sliding parts etc. On the other hand, PTFE and other PFAS have high chemical stability and thus remain and accumulate in the environment for prolonged periods without being broken down. For this reason, the impact of PFAS on the human health and the environment has become a concern, and regulations on PFAS have been gathering pace around the world.

Against such backdrop, we have further advanced the research relating to our original surface treatment technology, and by selecting a new resin powder, successfully developed an electroless composite plating that does not use any PFAS (including surfactants based on PFAS).

Because this new technology exhibits hydrophobicity and lubricity comparable to that of PTFE composite plating, the new plating can be used in environments where severe sliding motions are expected or maintenance is difficult. Furthermore, because of the low oleophobicity, the new plating is expected to maintain lubricity even in environments where lubricant oil and grease are present, and to which conventional PTFE composite plating is ill-suited. Due to its ability to tackle environmental challenges whilst also functioning as a high-performance plating, we believe this technology can find a wide range of applications in sliding parts (e.g. those used in automobiles) as a replacement for PTFE composite plating.

Key features of the new technology

• Electroless composite plating that uses a new resin powder and is free from PFAS, including surfactants based on PFAS (patent pending).

• Comparable to PTFE composite plating in terms of hydrophobicity and lubricity.

• Can be simultaneously used with lubricant oil and grease as it is less oleophobic than PTFE composite plating.

For further enquiries, please click here.

Return to news list