Technical Report

“Etchant Agent”

High-Performance Surface Treatment Agents

Metal Selective Etching Liquids (Etchants)

-Enabling targeted removal of metal film layers-

For many years, Nihon Kagaku Sangyo Co., Ltd. (President: KADOYA Hiroki) has been meeting the needs for surface treatment in diverse applications such as electronic components, plastic molding, and electroforming.

One area we are involved in is metal selective etching, whereby specific metals are removed from a substrate. Our products enable highly advanced etching tailored to the material and shape of the component to be etched, as well as the types and combinations of metals involved, earning the trust of many customers, both domestic and overseas.

【What is selective etching?】

Etching is a technology that uses chemical agents to dissolve metals. Its ultrafine processing capability is outstanding compared with mechanical processing methods, and it is therefore used for wiring formation on electronic circuit boards and a wide range of other applications. In terms of cost and suitability for mass production, wet etching using etchants is superior to dry etching using gases. The chemical agent that will react to a metal differs according to the type of metal in question, so it is crucial to select the right etchant.

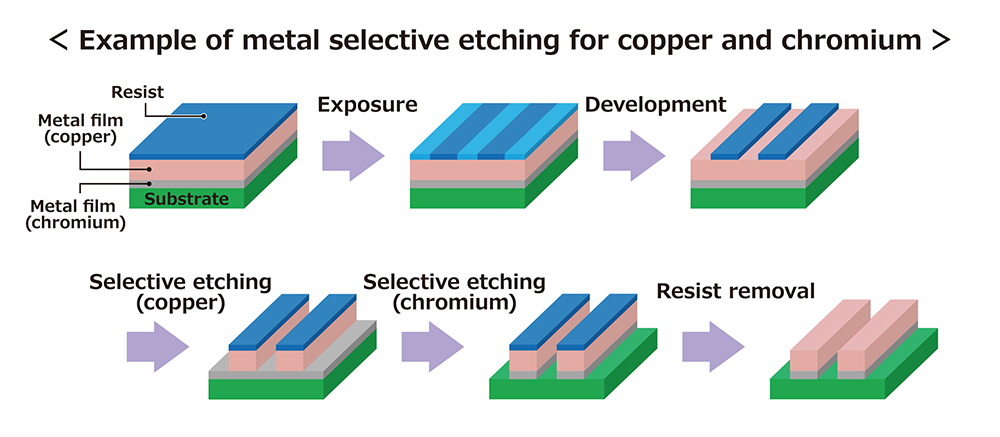

The type of etching known as selective etching removes only a specifically targeted type of metal from an electronic circuit board on which multiple metals exist, requiring even more meticulous selection of the etchant and control of the process.

【Our unique selective etching agents】

In the course of developing surface treatment agents over many years, our attention was drawn to latent demand among the users of our products for a process that could remove specific metals from surface-treated substrates and could also be tailored to the material and shape of the component, as well as the type and purpose of the metal film. This prompted us to start developing selective etching technology.

As a result of this technical development, we succeeded in developing etchants for each specific metal to be removed, including those for nickel, chromium, and copper. We achieved this by combining our know-how regarding the characteristics of different metals—cultivated through manufacturing nonferrous metal salts and developing surface treatment agents—with an electrochemical approach. In conjunction with the market launch of selective etchants based on our own proprietary technology, we came up with the phrase “selective etching” for the first time ever in Japan.

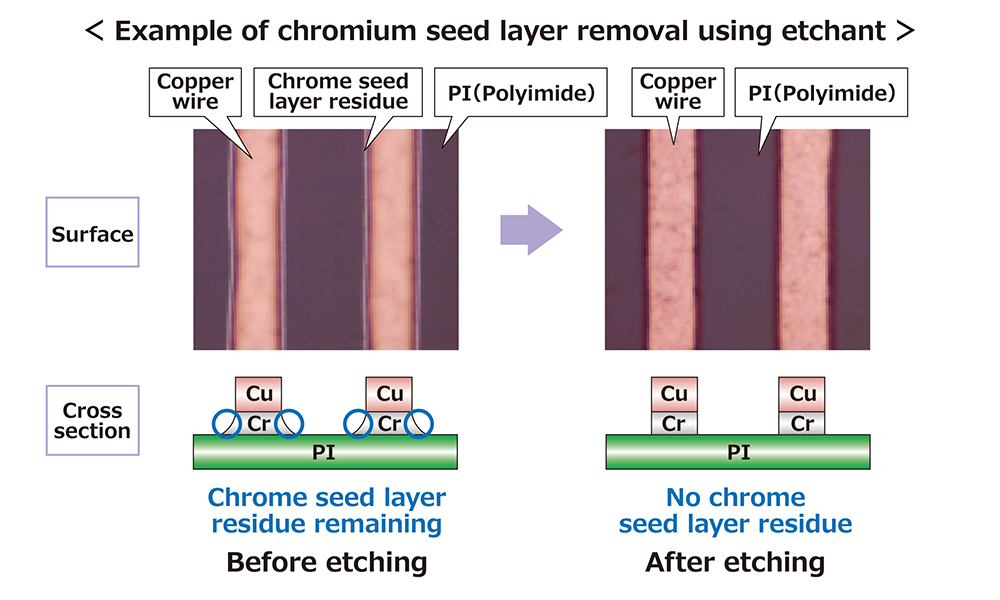

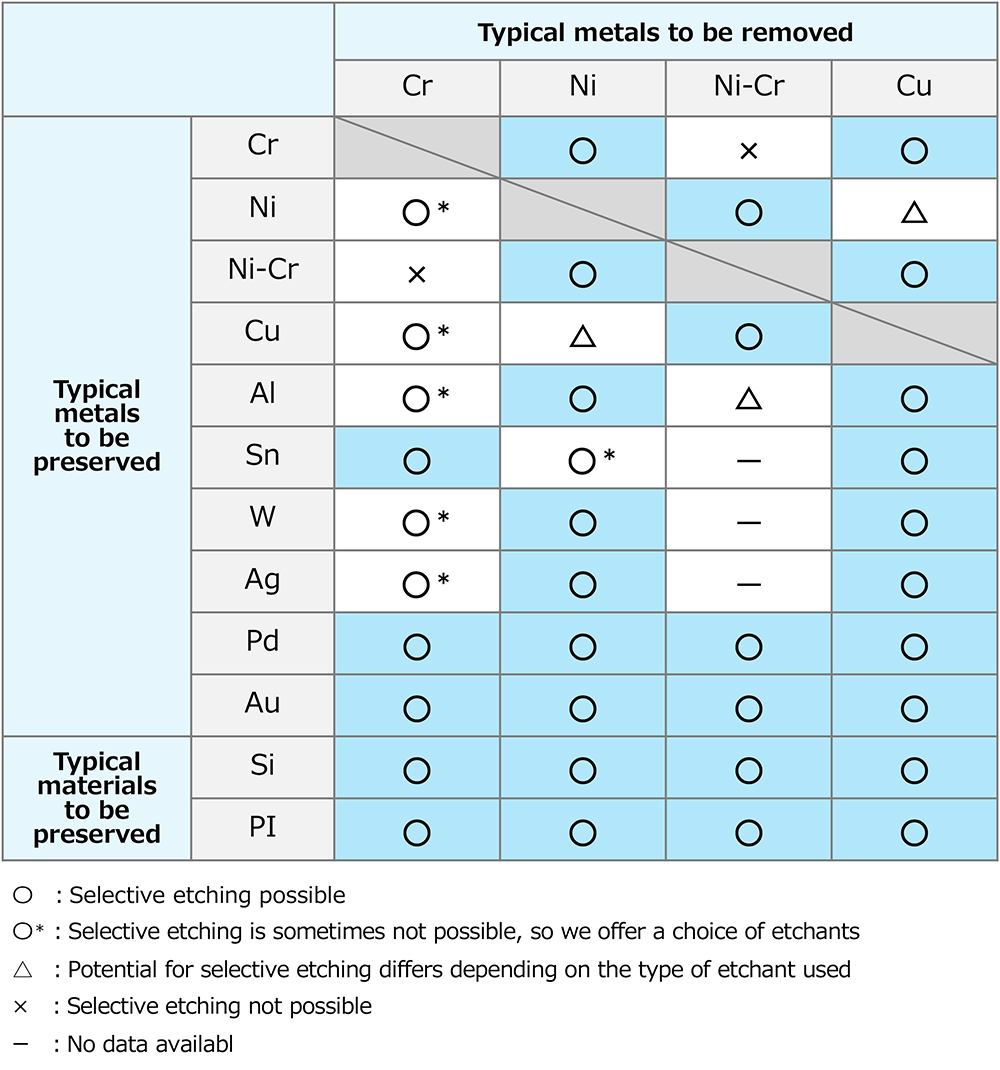

Our selective etchants offer a high level of metal selectivity, and are therefore used primarily by electronic circuit board manufacturers in Japan and overseas, which now require more precise etching as IT devices become increasingly sophisticated and densely packed with components. Our alkaline chromium etchant in particular is trusted by users due to the reliability of our unique technology developed as a result of handling a wide range of metals.

<Potential for selective etching according to metal combinations>

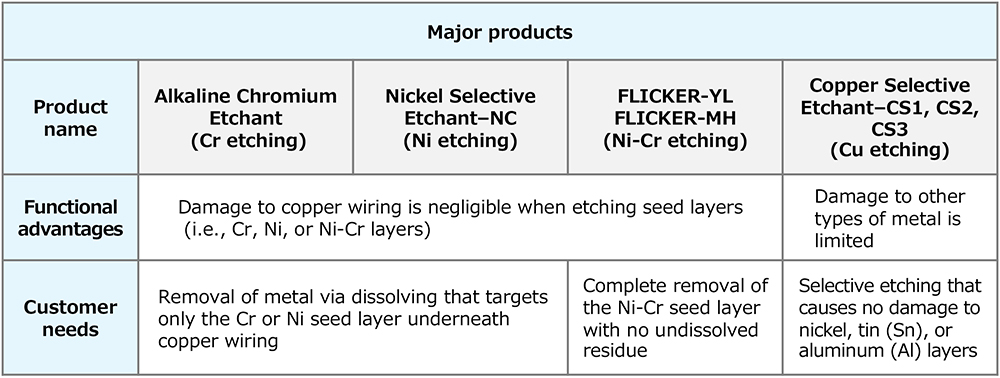

【Our rich product lineup】

Our selective etchants include alkaline chromium etchant, which can remove seed layers with virtually no damage to copper wiring; as well as nickel selective etchant; the FLICKER series of nickel-chromium etchants; and copper selective etchant, which selectively dissolves copper.

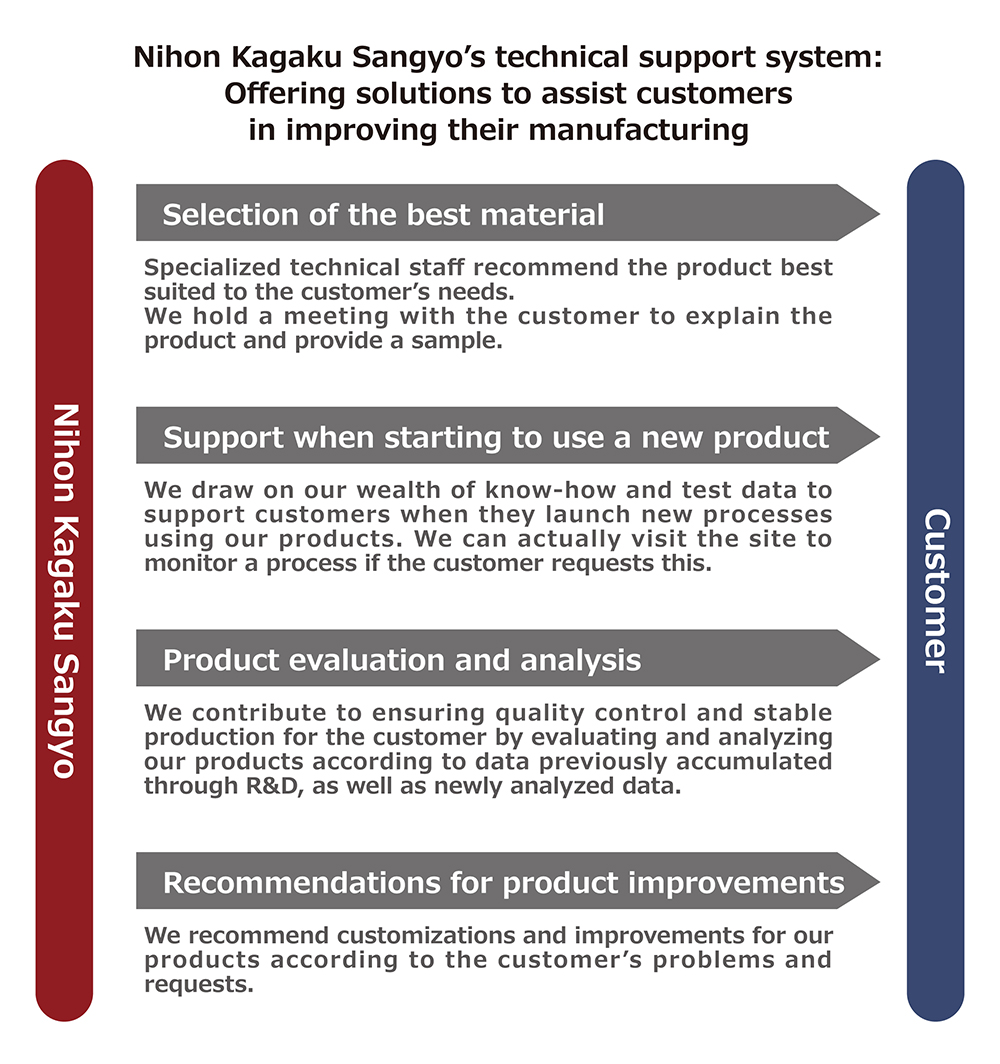

【Stable supply and technical support backed by domestic production】

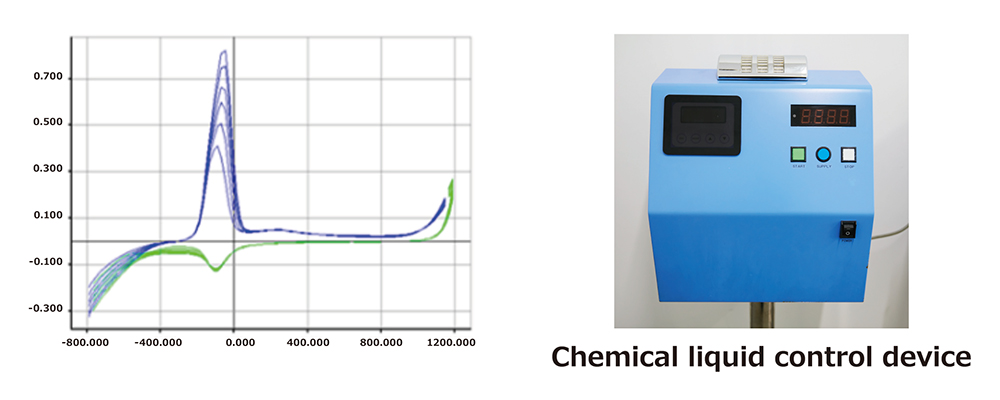

We develop, produce, and market products at our operating sites in Japan, thus ensuring the stable supply of our products and provision of attentive technical support. In addition to recommending etchants according to our customers’ needs, we have developed our own proprietary chemical liquid control system . This addresses the issue of chemical liquid control—which is essential in maintaining the quality of etchants—by using electrochemical measurement to enable chemicals to be kept in optimal condition.

Our professional engineers support customers according to their needs, from their initial launch of a new manufacturing process through to maintenance and improvement.

<Chemical liquid control system using electrochemical measurement>

The R&D Center takes action according to the customer’s problems and requests, and also evaluates and analyzes our products. For more than 80 years, Nihon Kagaku Sangyo has stood alongside to its customers and assisted them in solving their issues.

Detailed product information and technical information on Etchant Agent,

can be downloaded from here.